Use

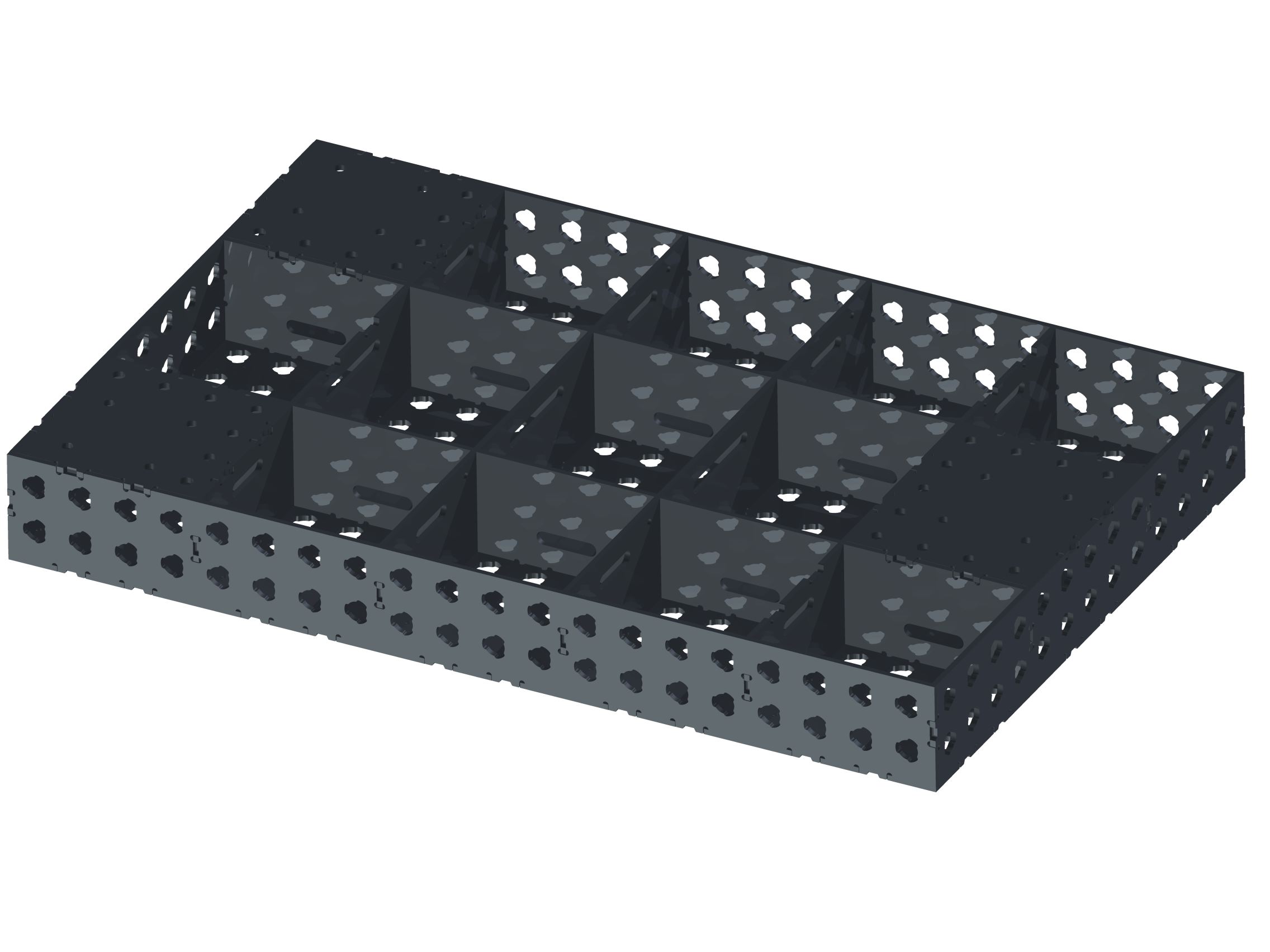

It is designed to work in small spaces, prototype workshops where it is not used every day and where high accuracy of position of welded parts is not required. It is a great addition to large, precision-made and also costly and expensive welding kits made by other manufacturers. The EXPERT welding table is ready to work immediately thanks to the use of several basic components – the angle, the stopper, the stiffener and the adapter. Thanks to the large number of clamping holes (there are 260 in the top plate of the table), the possibilities of setting and clamping have been expanded. The specially designed “adapter”, thanks to its shape, snaps into the holes securely and locks it in the correct position for clamping. Unlocking is ensured by tightening the nut. All the positioning elements are fixed by means of the adapter, and at the same time, a stiffener bed is formed. The adapter even without the nut will never fall off the table top!

The welding table kit is supplied in the form of individual parts that the customer assembles and then welds himself. Precisely made and aligned parts, including a thoughtful table design, will make the assembly much easier.

The EXPERT welding table kit can be ordered in two types of material.

MAT. Laser 355 MC Plus – standard structural steel with guaranteed weldability

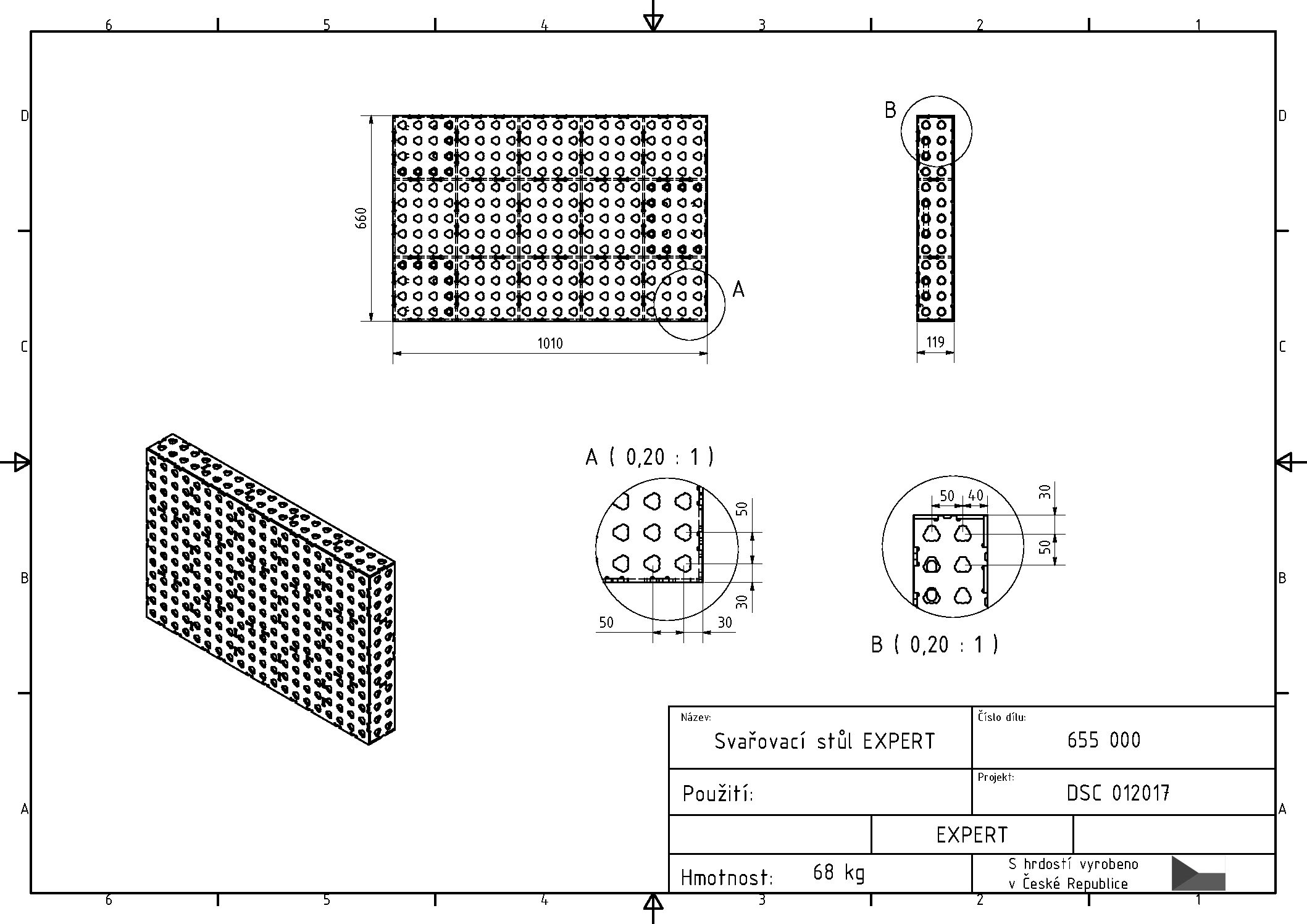

| Basic dimensions | 1010 x 660 – 119 |

| Material thickness | 6 mm |

| Material quality | Laser 355 MC Plus |

| Hole | D 22/27 |

| Hole spacing | 50 mm |

| Number of legs | 2 pcs with wheel 1 piece with silentblock |

| Total working height | Min 1040 Max 1066 |

All parts are manufactured on a CNC laser machine. All parts are aligned on a CNC machine.

Please see the instructional video, where we will show you how to build and weld the EXPERT table. In case of questions, please contact us by call or email. We are ready to advise you on the construction of the table.